Application of Brushes

Some of the common applications of our brushes in aerospace industry are:

- Deburring and finishing of hydraulic components

- Removal of burrs and sharp edges

- Cast engine block internal bore cleaning and debris removal

- Deburring and polishing the engine heads and components made of cast aluminium

- Cleaning turbine engine parts, cross-hole junctions, cram shafts, and bores.

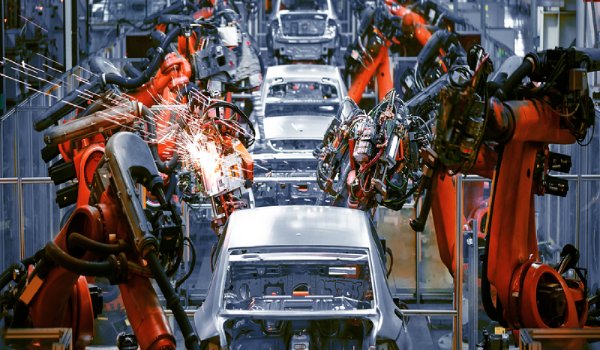

Some of the common applications of our brushes in automotive industry are:

- Deburring, polishing, and finishing the engine heads and components made of aluminium

- Deburring cross-hole junctions, cram shaft and crankcase bores; Debris removal from internal bores

- Polishing and finishing parts of machines

- Crimped wire wheel brushes are used for automotive paint removal, tube and deburring, mill scale removal, thread cleaning and for many more applications

- Twist knot wheel brushes are used for bed liner surface preparation, weld finishing, slag removal, decorative finishes

Uses of power brushes in industrial environment:

- Removing weld and carbon

- Removing plastic flash

- Edge blending

- To make surfaces rough before bonding

- Cleaning and blending of surfaces

End Users to achieve different brushed finishes on sheet products made of aluminium, brass, carbon steel, and stainless steel. Wide Face Brushes can be used to deburr drilled sheets and tube ends. We offer Brushes in High Carbon Steel, Stainless Steel, Brass, and Brass Coated Carbon Steel for deeper surface treatments and heavier De-burring. We provide abrasive brushes made of silicon carbide and aluminium oxide for finer surface finishes and lighter deburring. Our line of abrasive brushes for metal works to smooth down sharp edges and condition internal component surfaces with a consistent filament dispersion, resulting in a smooth, even finish. Brush conditioning offers substantial advantages in raising throughput and improving cutting action in addition to working to remove any potential loose metal and remove flakes that can contaminate or damage typical machinery functioning. To get the intended outcome in a repeatable manner, it is essential to use the proper bristle type, bristle length, bristle density, and operating conditions. We may offer that expertise by drawing on our knowledge base or developing a brand-new finish after evaluating your sample product. We only need a control sample of the finish you want to use, and that’s all. Fill up our custom brush form or send us a sample of your product for evaluation. We’ll offer you an economical solution with a key objective to bring down your production costs while using our brushes for metal finishing application.

Deburr – To remove chips, fines, or other material fragments from your product, deburring brushes are utilised. Our brushes are capable of improving your product.

Metal – Metal items are finished by removing burrs, changing chips, or chards from your product with a wire-filled brush or a synthetic-filled brush. One brush revolving on one side of your product or passing between two brushes rotating in the opposite direction can do this.

Wood – To achieve the appropriate finish, wood goods are brushed using a wire or nylon brush that has been treated with abrasive material. After that, dust or chips are removed from the products using a nylon or natural filament brush.

Brushes are used in a wide range of military applications, both on and off the field and in production. For the protection of our courageous soldiers and the security of our beautiful country, it is essential to ensure that military armaments and vehicles are spotless and functional both inside and out. Heavy-duty, long-lasting military maintenance brushes are offered by Brush Firm. Industrial brushes from Brush Firm are created, developed, and delivered in a wide range of sizes, styles, and materials. As a result, there is now a sizable inventory of thousands of brushes, bristles, and refills suitable for the trickiest tasks. Brushes from Brush Firm maintain heavy-duty military equipment and vehicles clean and in top functioning condition. Use Brush Firm durable and reliable brushes for:

- Cleaning of gun

- Cleaning of Grenade launcher, canon barrels

- Maintaining precise holes to prevent strength and temper loss

Brush Firm has been offering the commercial print industry high-quality printing and packaging brushes of various varieties. To deliver both standard and custom brush assemblies that guarantee dependability and quality throughout the printing and conversion process, we collaborate directly with well-known equipment manufacturers on a global scale. High tolerances and exacting fit are always met as per our quality requirements to decrease downtime and increase accuracy. For the printing, paper production, and converting industries, Brush Firm is indeed producing a wide range of cylinder brushes.

We are available to deliver high-quality outcomes for our clients whether they belong from printing or converting newspapers, magazines,

brush to match practically any size or shape of equipment, saving time and money by adhering to the requirements of the current equipment.

USE CASES FOR THESE BRUSHES ARE AS FOLLOWS:

Surface finishing: At various points during the machining process, brushes are used to smooth out and enhance surfaces. The surface particles can be removed by the brushes without changing the product’s dimensions.

Edge blending: By reducing stress concentrations and part fatigue, power brushes are utilised to round or blend corners.

Cleaning: Power brushes are used to remove surface particles in wet or dry applications.

Roughening: Surface roughening is done with power brushes to improve adherence before bonding or painting.

Hand Brushes are a suitable option for applications like scrubbing, deburring, and cleaning in hard to reach areas. Some of the applications where scratch brushes mainly used are

- Weld cleaning

- Removing burr

- Buffing

- Buffing

- Descaling

- Scrubbing

- Polishing

- Removing rust and scale

- General industrial cleaning

In the printing, glass processing, wood product manufacturing, food processing and manufacturing, metal finishing, and agriculture industries, rotary brushes have a wide range of uses.

FEW OF THESE APPLICATIONS ARE AS FOLLOWS:

- Cleaning conveyor

- Glass cleaning

- Scrubbing printed circuit boards

- Conditioning and polishing of metal sheet

- Deburring engine blocks and cam shafts

- Transporting materials and placing products